Each industry believes its process is more critical, more complex, more sensitive, and more demanding than any other. And in a sense, this is true. Within their own business, everyone faces the most difficult challenges they can possibly imagine, to: master the process, comply with quality specifications, optimize lead time and costs.

Nowadays, nothing can be left to chance and any waste that is left over is tackled. The lean culture has extended to even the smallest details. Moreover, production plants are supposed to be more and more flexible to adapt their operations to new products, new markets, new suppliers, and eve develop new norms.

In this context, despite a company’s best effort, optimization can seem unreachable, especially when there is an increased focus on one’s industry.

Aeronautics is probably one of the most representative examples of highly critical production in anybody’s mind because we have all taken a plane at some point in our life. As an example, let’s take a look at how Eramet Alloys uses Braincube.

Aubert & Duval, part of Eramet Group, manufactures metal parts that are assembled in the aircraft.

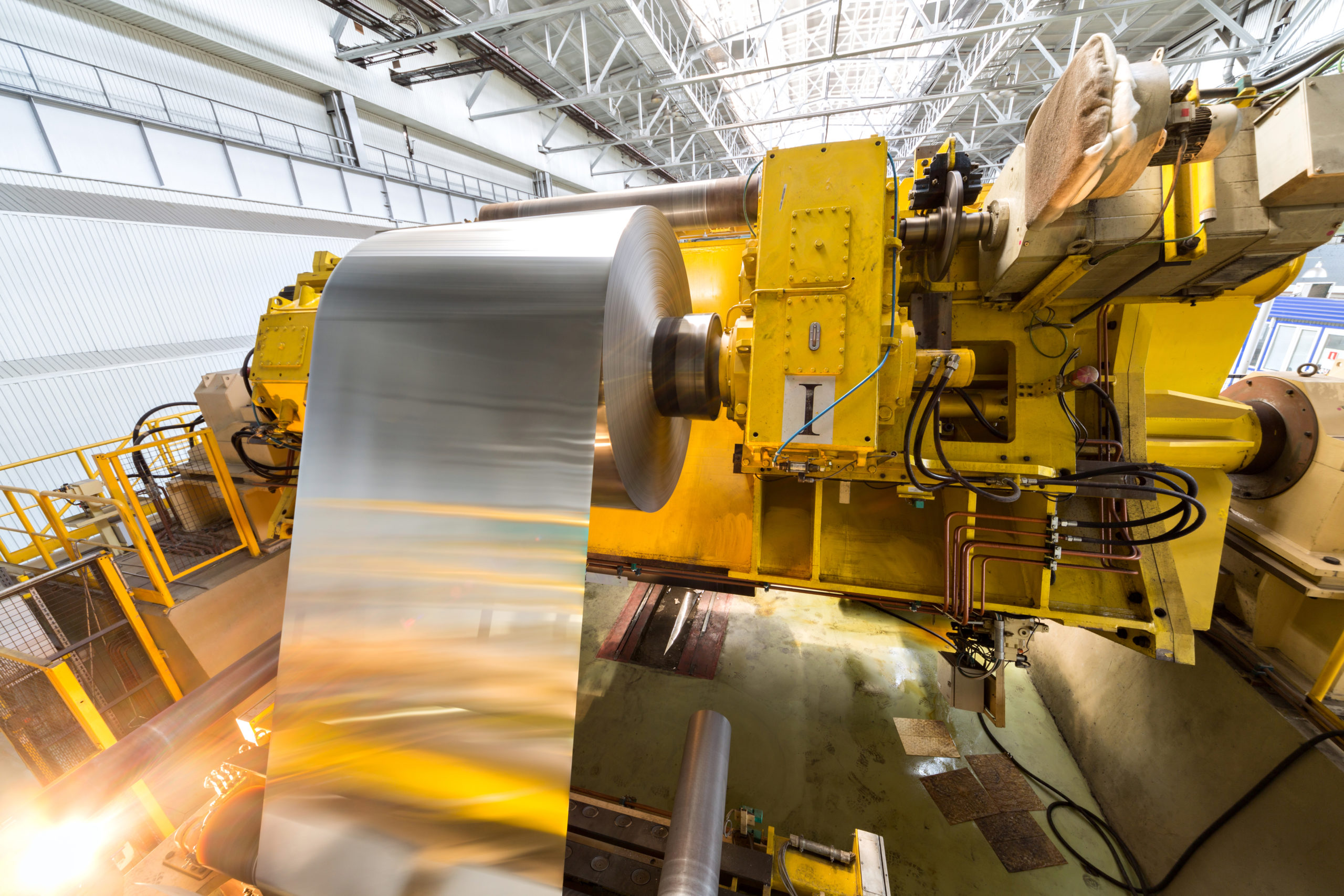

These alloys are melted and forged, some are then rolled, some are machined, and most are produced in a sequence of all these processes. This process usually takes place at different facilities, with a global lead-time of several weeks or months.

At each step, the parts can be split across several machines or may follow the same line, yet traceability of each product is required by aeronautics regulations (the EN9100 standard).

This means that the big challenge is linking the thousands of production parameters for a defined product from the first step of raw material up to the delivery. Aubert & Duval has zero-tolerance for any defects and must pay attention to quality at every step of the way.

They adopted Braincube to track their complex traceability and long production cycle. They built a contextualized data model to integrate and analyze all the production data scattered in various systems, at various plants. Within two months, Braincube was gathering all of the relevant data from each of the necessary sources.

Their goals for implementing Braincube included:

- develop a global view of all of the parameters that influence process and product

- understand the individual process parameters, or combinations of parameters, that influence the products’ key characteristics, to be able to detect and monitor slight deviations

- identify areas for process improvement.

One of the first benefits experienced by Aubert & Duval was archiving 100% of their data in Braincube. Moreover, this historical data was transformed into structured databases that reflected process conditions for each product, and that was contextualized to its final product.

The Aubert & Duval team could now analyze the past production conditions using millions of pieces of data on an instant’s notice.

Their first investigations led to the identification of a combination of parameters that showed a past defect rate divided by 4. The team could immediately implement this best practice as a production floor rule, and the defects started to decrease.

By leveraging the Braincube algorithms, they saw how easily they could optimize their processes. They extended their Braincube implementation to other production lines at the plant, and, soon after, to three other facilities.

At each facility, the technical teams led their improvement program by leveraging Braincube to improve process control, quality, environmental impact, and yields.

Braincube boosted Aubert & Duval’s solid expertise by retrieving all its historical best performances and their optimal experienced process windows.

The solutions drawn up by the technical teams were quickly transferred to operators. As a result, huge improvements emerged everywhere: +32% stability on operative standards, -18% defects on a reference product, and an increase of 1.3 of yield.

In order to systematize the approach and make it sustainable, Aubert & Duval adapted its internal organization: including the corporate sponsors, who set the objectives, a Braincube leader at the corporate level and a leader at each facility.

The Braincube leaders were appointed to prioritize actions, lead program implementation and support users. A massive improvement accelerator was now ready to support operations.

At the biggest plant, 4,000 SPC cards were deployed to make process control sharper, 130 real-time dashboards of KPIs follow-up were displayed, 30 users were trained in how to get immediate answers from their data, and all their studies were automatically recorded and updated in Braincube.

From then on, Braincube consolidated all technical meetings, reports and exported them in smart office presentation format. An extension to Erasteel, a sister company in Eramet Alloys Division, was also launched.

Decision-making became fact-based, leveraging historical data and past results. All alternative settings could be compared in Braincube before implementation.

Anyone familiar with aeronautics knows that certain special processes are controlled through Nadcap certification. Under this norm, and because final product quality cannot be trialed without destructive testing, mastering process control is necessary for parts validation.

Braincube became the operational tool for Aubert & Duval to prove to its customers and auditors that it mastered its operations.

Year after year, Eramet Alloys Division has kept improving, deploying Braincube across a wider spectrum, with an initial goal of covering 14 plants. Eramet Alloys Division was able to capture the essence of the Manufacturing Intelligence revolution and to drive change management to 4.0 industry.

People are ready to face the upcoming industrial challenges at all levels within Aubert&Duval.

While products, cost structure and constraints may be different across industries, the mindset can be the same: it is now possible to leverage big data to remain competitive. The time to take advantage of Manufacturing Intelligence is now.