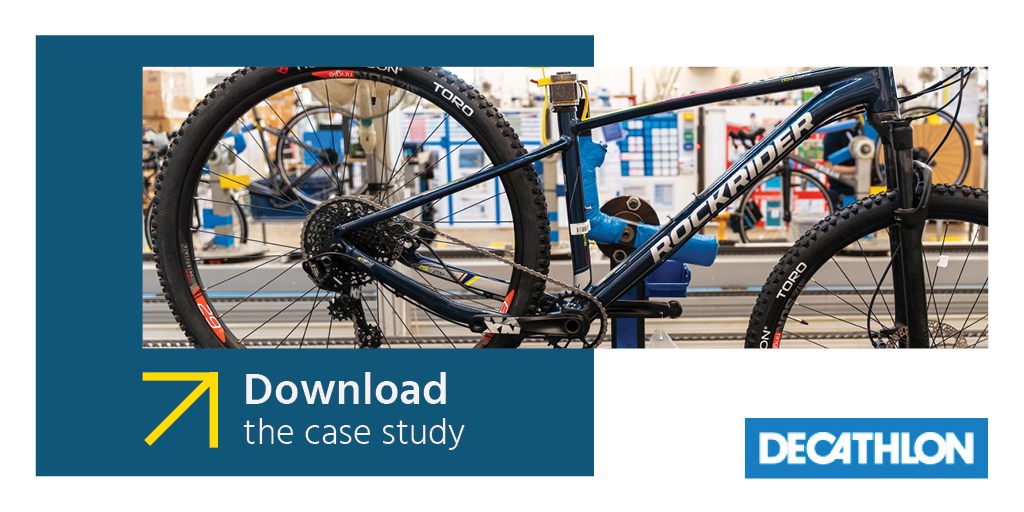

Decathlon produces high-quality, sustainable and cost-effective retail athletic products. They selected the Siemens Edge Factory Box powered by Braincube Streaming Apps to help accelerate their digitalization efforts at their plant in northern France. Specifically, they wanted to better monitor and control production by leveraging data streams.

In most companies, operators are already working on computers, but they are often the only ones with access to all the data in the production chain. The data exists, but are not centralized or easy to exploit in a global way.

— Alice Conan, Digital Business Center & IIoT Manager at Siemens

The Decathlon bicycle production plant is not the only one to be faced with this problem of the transition to Industry 4.0, with smarter factories, which integrate new technologies such as artificial intelligence, cloud computing (remote and dematerialized storage of data), cobots (robots capable of working in collaboration with humans), virtual or augmented reality or quite simply a real-time digital information system. However, in this region of French industry, and in particular SMEs and mid-caps, is lagging behind its main European, American and Asian competitors. The Industry of the Future by 2025 reminds us, “only 14% of the companies questioned have partially deployed an ‘Industry of the Future’ digital solution and 2% have fully deployed it.”

There is therefore a lot to be done in this area. And the expected benefits are even greater: improvement in performance, profitability, competitiveness, agility and even safety.

The digitalization solutions from the Siemens and Braincube Edge Factory Box therefore meets Decathlon’s desire to move monitor, and control production from live data streams. Their tailored solution offers data centralization with internal storage (with an Edge solution), external storage (via the Cloud) and hybrid (Edge and Cloud connection). This is to ensure that data is processed, accessible to all and usable.

Poquet confirms: “In the medium term, processes will be set up apart from this data to allow us to react as quickly as possible to production contingencies.” This is one more step towards a French industry that is building its future.