Revolutionize your paper manufacturing with AI-driven optimization. Enhance efficiency, cut costs, and achieve autonomous operations like industry leaders Arjowiggins and Oji Paper. Embrace the future of smarter production!

Learn more

Visualize real-life scenarios that resonate with your industry and goals in this exclusive white paper. Explore specific technologies that can help chemical manufacturers improve specific processes.

It goes without saying that Environment, Health, and Safety (EHS) is at the forefront of every chemical manufacturer’s efforts. In fact, the chemical industry was the first manufacturing sector to launch a formal EHS approach in the 1980s, commonly known as Responsible Care.

While this global initiative is voluntary, the chemical companies that participate in Responsible Care “account for nearly 90% of all global chemical production.” It’s clear that chemical companies of all sizes view Environment, Health, and Safety measures with the utmost importance—and for good reason. Hazardous materials, chemical reactions, and complex machinery make chemical manufacturing more dangerous than other industries.

As noted by McKinsey, “companies with superior organizational health—those that align most successfully around a clear strategy, execute it well, and renew themselves over time—also tend to have the best safety records.” In other words, manufacturers who prioritize and invest in wider strategic goals also see gains in their EHS efforts.

Today’s Industry 4.0 tools can help manufacturers improve EHS by bringing better visibility into factory conditions and product creation. Here are a few examples that show how Industrial Internet of Things (IIoT) technologies can help chemical companies bolster their EHS strategies.

Safely storing, using, and disposing of a variety of chemicals calls for meticulous tracking. Improved product traceability can help chemical manufacturers accurately and efficiently report which chemicals were used in different processes and products.

Today’s technology, including digital twins, makes it easier to capture what happened before, during, and after production. This means you can have all your production data available in a digital form as soon as a product comes off your line.

Braincube-built Digital Twins provide end-to-end knowledge about each individual product—including raw material supplier data, the specific parameters during the production process, and the composition of the finished product. This data provides chemical manufacturing teams with traceability insights that were previously unavailable.

Should a problem arise during (or after) production, digital twin data makes it easier for teams to identify issues and act accordingly. For example, let’s say one of your raw material suppliers notifies you about a faulty batch. Since the supplier data lives within your Braincube-powered Digital Twin, teams can quickly identify which batches or products were impacted by the defective source materials.

As a result, teams can investigate specific batches without having to review all products in bulk. Better yet, they may be able to catch impacted batches before they leave the factory. These efforts keep consumers safe, resulting in stronger brand loyalty and trust.

Digital twins also play a pivotal role in complying with environmental regulations. Improved production visibility means teams can ensure they are operating within carbon emission regulations.

Additional IIoT tools, like Braincube’s Studio Application, make it easier to view and understand valuable Digital Twin information. Studio is a unique hybrid portal that can bring together real-time and historical data into one workspace.

This means teams can compare historical energy consumption data to live conditions side-by-side. They can use Studio to monitor a variety of environmental initiatives ranging from tracking energy usage for specific processes, monitoring plant-wide energy consumption, and keeping an eye on emissions.

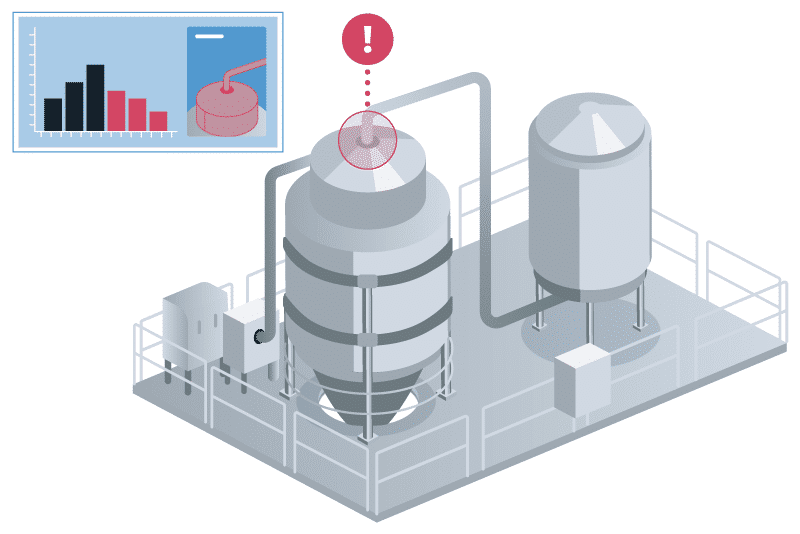

Damaged or malfunctioning equipment can cause accidents at any point in the production cycle. Automated condition monitoring tools—especially when paired with automatically-triggered alerts—can help teams stay on top of degrading factory conditions. These technologies are improving health-related measures for employees.

For example, gas leaks can be both fatal to employees and environmentally damaging. Pairing automated monitoring with an alerting system can notify teams about gas leaks on specific pieces of equipment even if the leak is not detectable by scent or visible inspection.

These alerts can prevent asphyxiation and keep dangerous gases out of the atmosphere. This ensures that both shop floor workers and neighboring communities are safe from harmful chemicals.

Another potential hazard lies in manual monitoring. While some processes and equipment can utilize electronic sensors, detecting mechanical corrosion is typically done via visual inspection. Monitoring corrosion with the human eye has its limitations, though, especially if you have many pieces of equipment within your facility and dwindling human resources. (Of course, there are tools such as computer vision that can automate processes even further if part of your strategy.)

Today’s IIoT tools can even automate the tracking of key parameters—including flow rate velocity and pressure. Receiving alerts about changing parameter conditions can help detect corrosion earlier than the human eye. This means machines can run more efficiently, keeping both safety and environmental hazards at bay.

Additionally, since various technologies can detect these parameter changes, it is easier to understand what is happening with your equipment before something goes wrong. Early detection of faulty or degraded equipment can keep production operating within environmentally-friendly ranges while keeping employees safe.

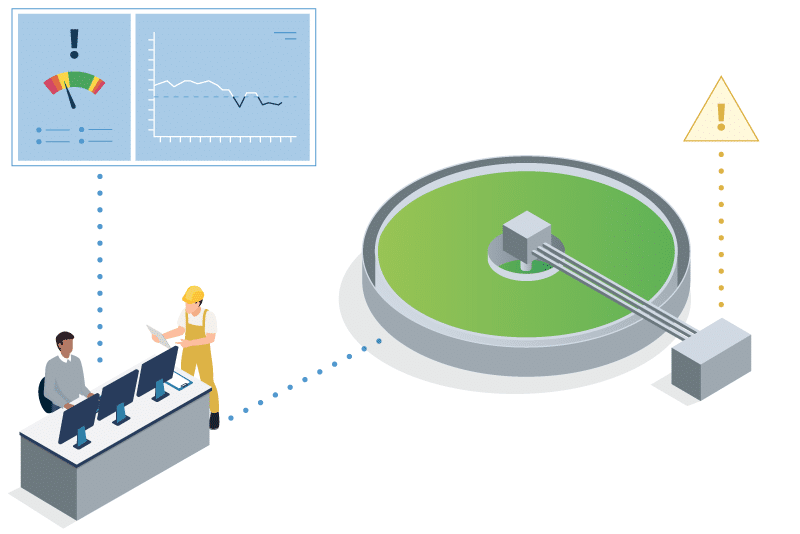

Condition monitoring tools may also feed into your predictive maintenance strategy. Combining real-time shop condition data with historical maintenance performance makes it easier for teams to sustain safe working conditions.

Vibration analysis has long been a foundational component of condition monitoring, though oftentimes it lives in a siloed alerting system or has latency. The Frequency Analysis node from Braincube automates vibration monitoring, simplifying the visualization and analysis of high-frequency signals coming in from equipment. These visuals make it easy to see and understand what’s happening. With a customizable workflow, SMEs can use info coming from the Frequency Analysis node for better root cause analysis when a problem arises.

Because PdM is still growing in its maturity, ready-to-use tools make you more efficient and offer faster time to value. For example, pairing Braincube’s Alerts App with SPC means teams can be alerted anytime production is out of compliance. This kind of practice can enhance your predictive maintenance strategies.

After analyzing out-of-spec conditions, teams can set future alerts for when equipment trends in a similar direction. Automatic alerts are sent to key team members when unexpected conditions arise (e.g. vibrations slow down or drastically increase, quality specs are out of compliance, etc.), enabling teams to react quickly and prevent larger issues from occurring.

There are also predictive maintenance tools that make it easier to anticipate breakdowns or mechanical failures before they occur, ensuring the safety of workers. At the core of maintenance optimization lies Digital Twins. Tools like Braincube’s product-based Digital Twins play a major role in providing manufacturers with highly detailed product traceability regarding how a product or batch was manufactured.

For example, if you want to understand spray dryer efficiency, you may want to consider an asset digital twin. Digital Twins are able to encapsulate process and equipment data including both feed characteristics and processing parameters. Traditionally, these outputs are not always easily tracked back to their sources of variability (at least not at scale), which is why Digital Twins offer enhanced traceability and equipment optimization.

While there are many tools to assist with condition monitoring and preventative maintenance, we believe that a holistic platform like IIoT can help make your employees’ jobs easier as well as keep them safe: a win-win.

Environment, Health, and Safety measures have been at the forefront of chemical manufacturing for nearly 40 years. Even so, today’s technologies can help companies make further advancements in their EHS strategy. Improved condition monitoring, better product traceability, and wider data visibility all play a role in making chemical manufacturing safer for both employees and global communities.

These tools also play a large role in communicating EHS information between employees, teams, or facilities. When information and successes are easier to share and scale, companies can advance valuable EHS initiatives faster and with greater confidence.

For more information about how IIoT can help chemical companies improve specific manufacturing processes, check out our exclusive white paper.

Utilizing Braincube’s Digital Twins and advanced applications, one global energy company improved key processes, reduced waste, and saved over $1 million.

See how leading IIoT technologies can play a vital role in improving chemical manufacturing processes in this exclusive white paper.

Self-service apps make things easier and more efficient for your teams. Our suite of apps built specifically to help manufacturers reach their goals.