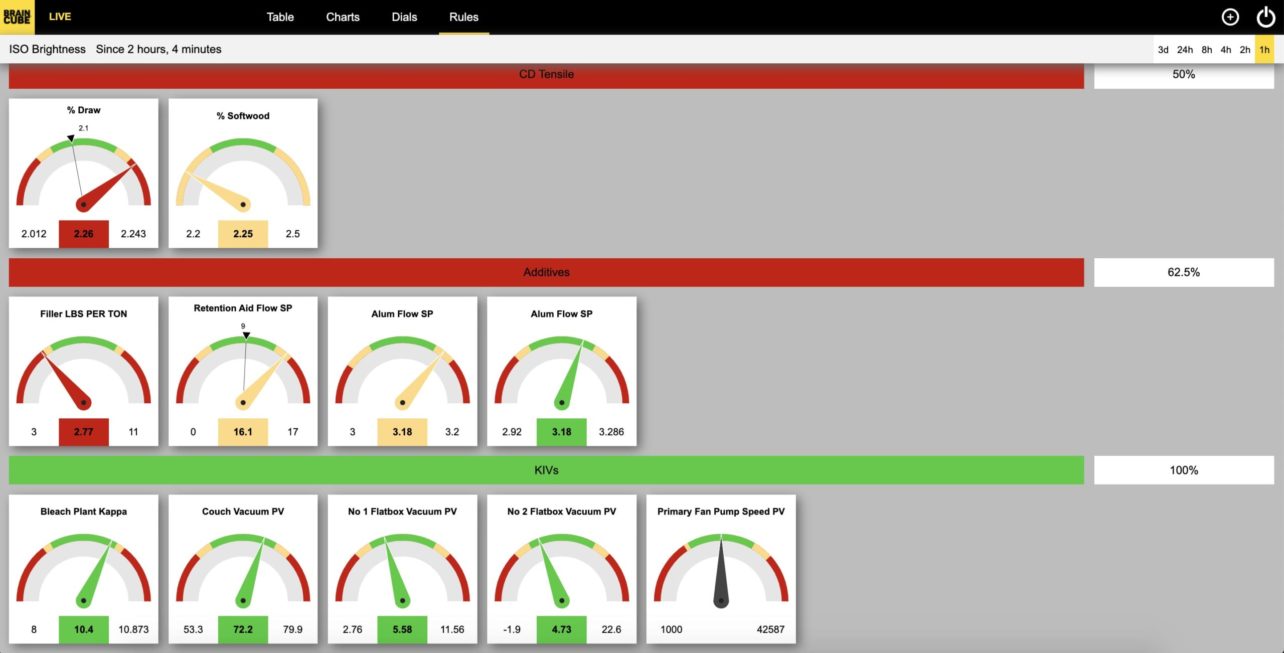

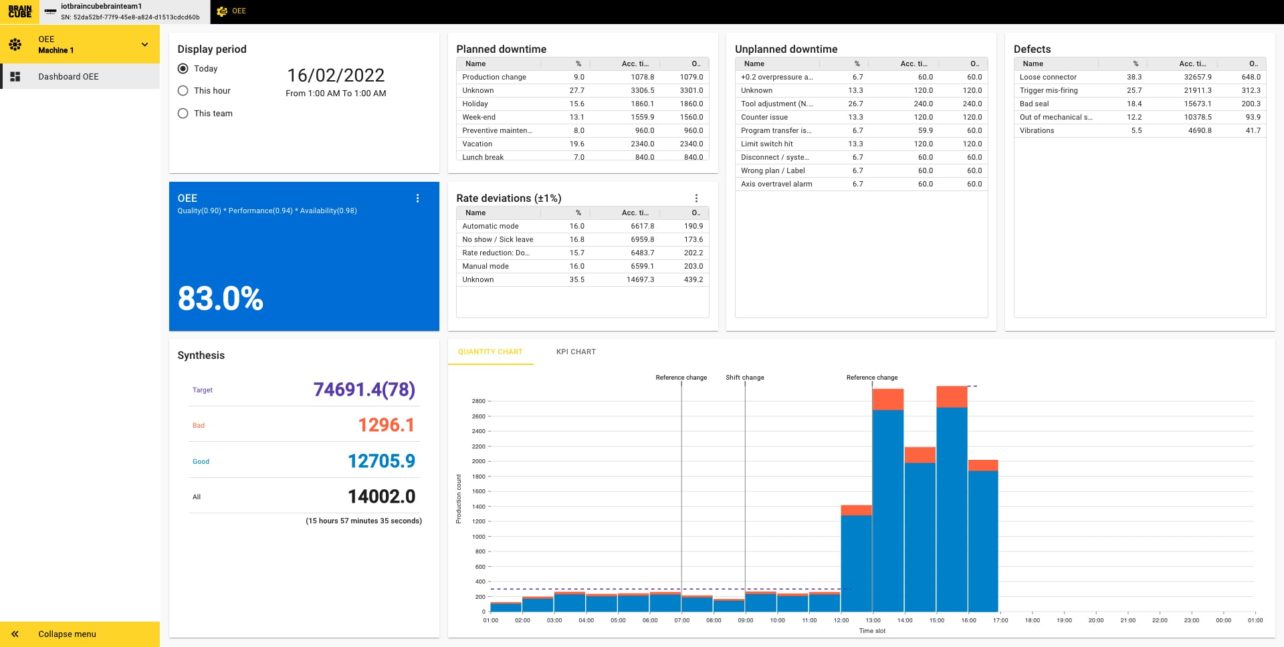

Transformative operational changes happen with access to the right data. Braincube’s self-service applications ensure that shop floor teams can monitor for drifts, stay up-to-date with the correct standards, and maintain compliance.

Arjowiggins, a specialty paper manufacturer, wanted an operational solution that enabled them to use process data in more meaningful ways. The company implemented Braincube’s tools across all of its operations teams. Managers monitor compliance, operators can access the latest rules in one centralized application, and engineers can push optimized standards directly to the shop floor.