Revolutionize your paper manufacturing with AI-driven optimization. Enhance efficiency, cut costs, and achieve autonomous operations like industry leaders Arjowiggins and Oji Paper. Embrace the future of smarter production!

Learn more

Presenting a new tool or procedure to your management team often results in resistance, ranging from lack of funds to an unclear return on investment (ROI).

Here are some helpful tips for building a convincing case for your executive team to bring an IIoT digital transformation tool to your business strategy.

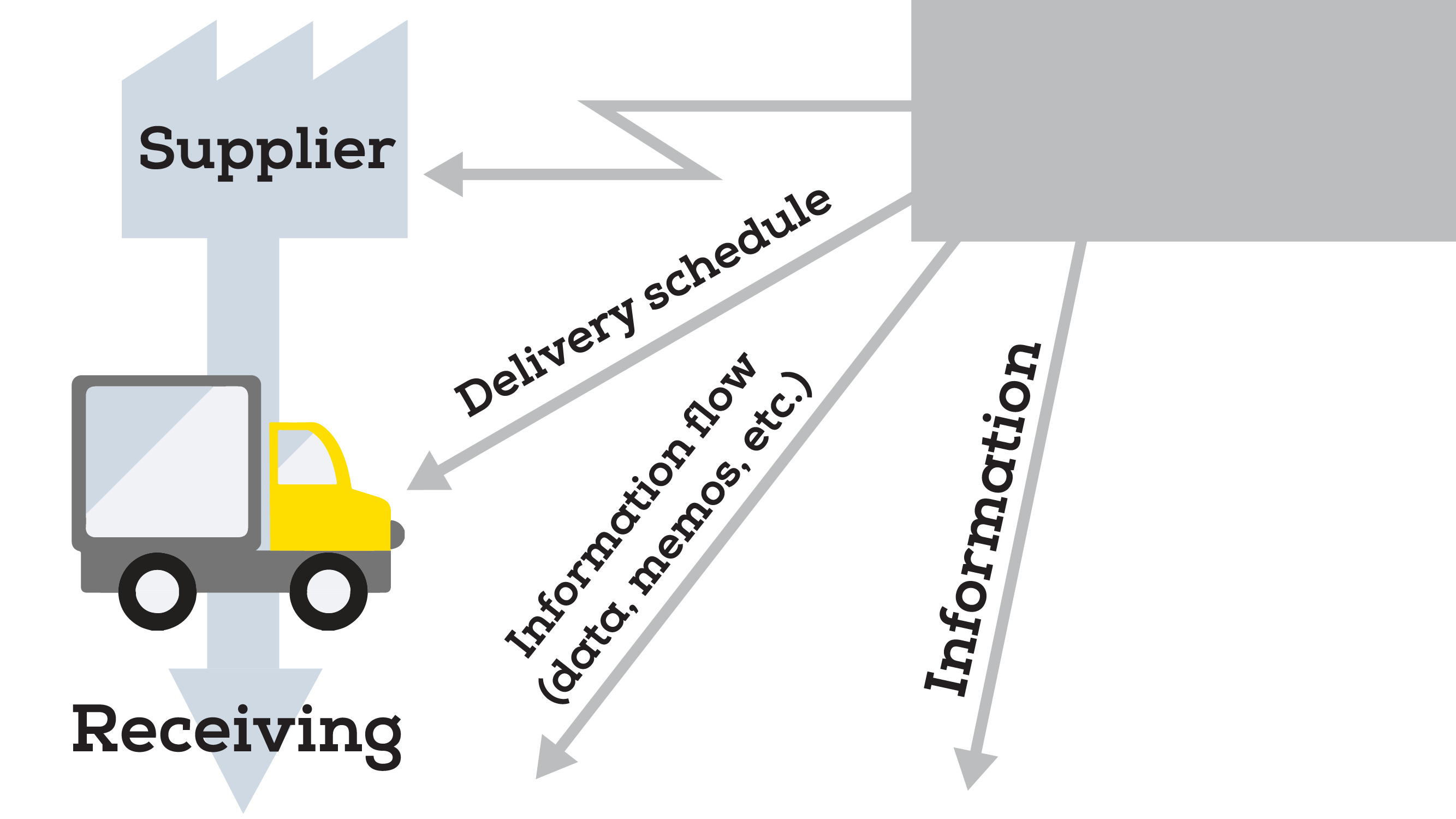

If your company isn’t ready for Industry 4.0 yet—either from a technological standpoint or an organizational standpoint—consider drawing up a value stream map (VSM). Value stream mapping (sometimes known as material- and information-mapping) enables you to understand the current state of your operations for planning future improvements.

Put another way, mapping your value stream helps you see which processes you can improve with your existing technology. Flowcharting each step in your manufacturing process helps identify areas to minimize waste, reduce cycle times, and implement process improvement practices. Taking the initiative to make the most with what you have is beneficial for building a case for additional resources because you’ll be able to clearly pinpoint your gaps.

Going through this process will prepare you for leveraging 4.0 tools when you are finally able to bring them on board. Creating a VSM is an indicator that you are looking for solutions that impact wider business practices, not just one part of the business. The most valuable digital transformation tools will impact your entire value stream, including your customers, and bring added value to your entire business.

A VSM can help you get a firm grasp on your weakest links and biggest problems. For every problem, there are a dozen different tools, programs, and methodologies to help you solve it. Fully understanding your problems enables you to effectively advocate for the right solution to address your business needs.

Make sure that the technology or methodology you want to implement matches the problems you want to solve. Keep in mind that you may not need the latest and greatest tools for where you are right now. The solution could be a brand-new technology, but maybe it’s a tried-and-true Lean Manufacturing method. Diluting your problems down to their simplest form will make it easier to pick the right solution from the vast pool of possibilities.

When faced with different problems across multiple teams, resources and finances are often stretched thin. It’s tempting to gravitate towards a competition-like proposal process to make project selection easier. This proposal format typically requires each team lead to state a problem, vet a qualified vendor or solution, determine the project cost, and forecast the ROI.

Cross-departmental collaboration is at the core of Industry 4.0 technology. True transformation happens at the company level, not within individual teams or problems. Teams operating in silos will struggle with adopting digital transformation practices and processes. Changing your project-vetting process to encourage cross-departmental solutions is a great way to start bridging gaps between teams.

Looking at problems holistically is the most effective way to move the entire company forward. Setting broad company goals is a great way to kick-off collaborative efforts: wider initiatives, by their very nature, require multiple teams to help solve. These collaborative solutions are the key to moving your company forward by leaps and bounds.

Let’s say one of your teams presents a proposal that practically guarantees a positive ROI. Any project with a high likelihood of success is not a true experiment: it is simply a way for teams to get funding for a known solution to a current problem. If there’s a 75% chance of success, you’re not taking a risk. You are merely implementing solutions that you already know will work.

Experiments, on the other hand, are projects that land on your desk and make you feel a little uneasy. They likely won’t have a definitive ROI or calculable financial gain, despite being comprehensive in their problem statement and goal.

This is because some of the biggest problems taking place on your factory floors can’t be solved with what you know right now. There is often missing data, a lack of knowledge-sharing, or insufficient information that makes it nearly impossible to understand a problem’s full complexity. You don’t know what you don’t know: that’s where experimentation comes into play.

As a manager, you need to be open to—and willing to support—true experimentation. Testing and learning at a smaller scale, especially when the outcomes are unclear, is vital if you want to uncover new opportunities. Your openness to experiments will trickle down to your teams and encourage them to think outside the box. They may be more inclined to share ideas even if they don’t know the specific outcomes, prompting others to contribute to the idea pool.

It can be overwhelming to choose the “right” tool for your current challenges. There’s no shortage of solutions available in today’s market, all offering seemingly similar solutions that vary ever so slightly. However, limiting yourself to a specific tool or the promises of a given technology is not where true transformation occurs.

Rather than focusing on what a tool says it can do for you, think about what you want to accomplish on a broader scope. Make an effort to strive for this goal, regardless of which specific tools or practices help you reach your goals. New technologies will not fix existing organizational issues.

If possible, bring your factory teams into the vendor selection process. It’s important that project leads and factory floor employees are engaged end-users of any incoming processes or technology. Including these teams in the conversation and selection process gives them an opportunity to bring their specific knowledge and perspective to the selection process.

Additionally, asking for factory floor teams to participate early on will more likely result in their support of new technology during implementation. Gaining their support and enthusiasm early in the process will help training go smoothly and ensure a better adoption rate.

Factory teams are also more inclined to promote the value of a given tool if they’re invested in the selection process. Garnishing the support of factory teams is crucial to bringing in other digital transformation solutions. If your factory workers are promoting a given tool to upper management or executives, this helps you build a case for more Industry 4.0 resources moving forward.

Stating your problem in simple, reduced terms will also make it easier to vouch for the right solution. When the time comes to bring in an IIoT vendor for digital transformation, keep your initial pilot project small in scope. In addition to making the pilot easier to manage, it is also more likely you’ll get permission for smaller projects that might not require as high of an up-front cost.

Perhaps most importantly, a small scope enables you to understand where improvements are made and why. Set reasonable benchmarks and know them well so you can clearly convey the pilot’s ROI to management. It will be easier to convey successes to management when asking for more resources.

A comprehensive understanding of your entire value stream sheds light on where you can achieve quick operational wins and enables you to build a digital transformation framework. Work with your teams to identify the correct problems to solve and the right partner for your Industry 4.0 goals.

Including factory teams in the vendor selection process helps you start off on the right foot during implementation, ensuring early buy-in for a platform your employees selected. As factory employee enthusiasm and quick wins make their way to upper management, you’ll gain momentum for larger IIoT initiatives and true transformation.

Download our complimentary Value Stream Map (VSM) template for Manufacturing.