Revolutionize your paper manufacturing with AI-driven optimization. Enhance efficiency, cut costs, and achieve autonomous operations like industry leaders Arjowiggins and Oji Paper. Embrace the future of smarter production!

Learn more

Download our free white paper and learn how Industry 4.0 grants employees creative autonomy and maximizes their potential, even in the wake of AI and robotic automation.

The promises set forth by Industry 3.0’s methods have been fulfilled and have now plateaued. The problems companies face today go far beyond Taïchi Ohno’s seven wastes of Lean manufacturing. The enemies of today’s manufacturing world are indecision and delay.

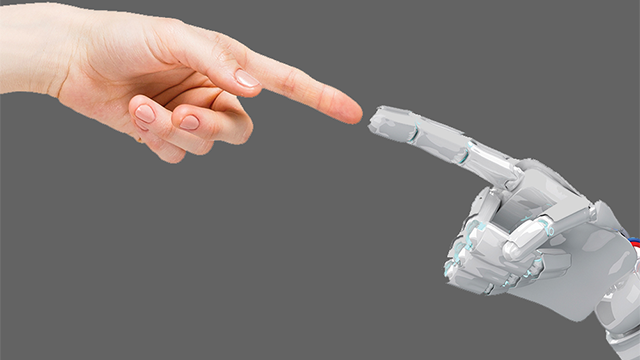

Industries across the entire manufacturing spectrum can achieve true digital transformation in the form of Industry 4.0 practices and tools. But what does Industry 4.0 mean for the human workforce? Will humans be fully replaced by artificial intelligence (AI) and robots?

As more businesses consider Industry 4.0 for their production lines, it’s important to understand why Industry 4.0 is more than just AI robots revving up manufacturing output. Laurent Laporte, CEO and Co-Founder of Braincube, makes the case for how digital transformation enables companies to stay competitive and empowers manufacturing’s human workforce.

Meet some of the hundreds of companies currently using Braincube to digitally transform their manufacturing processes.

See how Cargill leveraged Braincube’s Digital Twin to improve their weekly recipe output, decrease energy consumption, and motivate teams to leverage data to implement best practices in their factories.

Get the latest updates on digital transformation and manufacturing best practices delivered to your inbox.