Revolutionize your paper manufacturing with AI-driven optimization. Enhance efficiency, cut costs, and achieve autonomous operations like industry leaders Arjowiggins and Oji Paper. Embrace the future of smarter production!

Learn more

Kimberly-Clark uses predictive AI to meet demand

RESULTS

For manufacturing, supply and demand are expected to fluctuate year to year, season to season. When Kimberly-Clark hit a surge in demand, they knew they had to avoid unplanned downtime. Even with intrinsic process knowledge, there are so many variables, making it a challenge to optimize production for any given situation.

To support their commitment to a healthy planet, Kimberly-Clark targets KPIs such as water reduction, fewer greenhouse gasses, and using more recycled materials in their packaging materials. Kimberly-Clark’s engineers were building valuable predictive models to address these KPIs in changing conditions. However, the time and effort required to build each predictive model was inhibiting efficiency and progress.

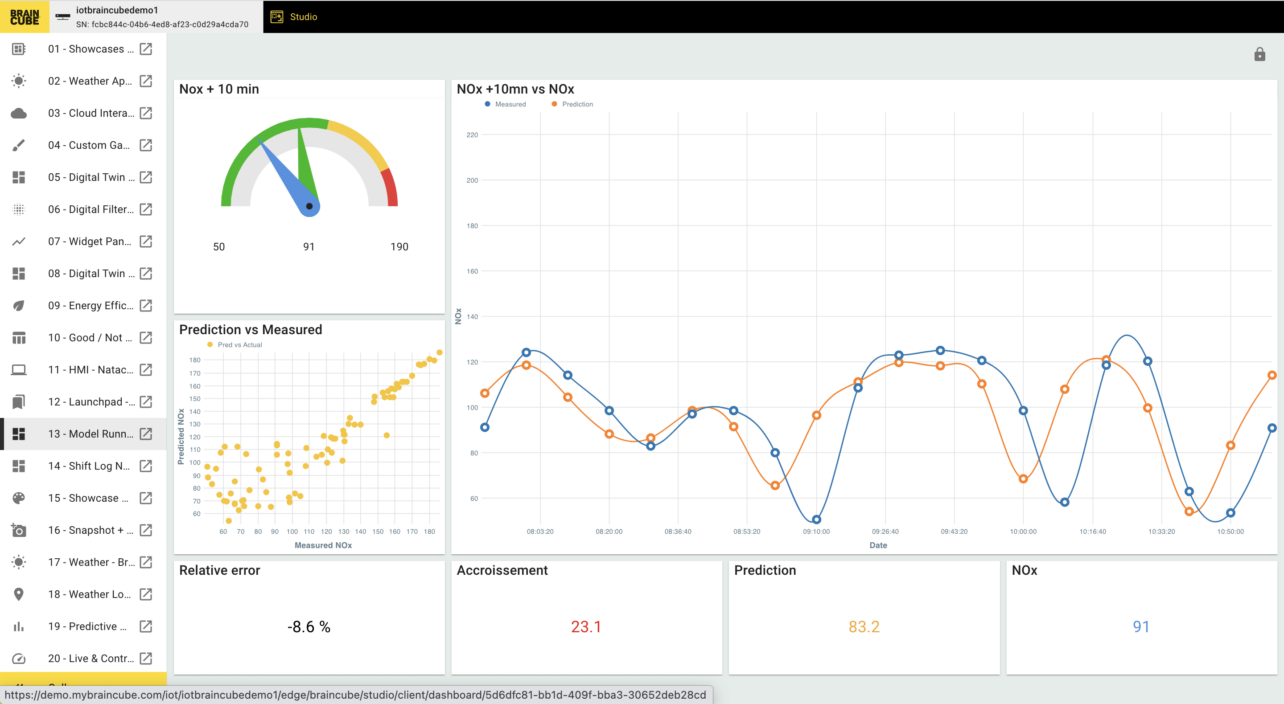

To maximize their data’s value, Kimberly-Clark worked with Braincube to create digital twins of their tissue line. Aggregating their historian, PLC, and other data sources into a single source of truth meant that they could more quickly make discoveries. Now that data was accurate and verifiable, Kimberly-Clark’s teams developed predictive models that were repeatable, explainable, and actionable—in a fraction of the time it used to take them. Once a prediction is generated, engineers can push them directly to PLCs for closed-loop control.

Kimberly-Clark’s engineers also used Braincube’s Advanced Analysis App to gather, organize, and refine production data from various sources (including IT sources and individual machines). The app cross-checks thousands of variables and ranks each variable based on how much it impacts the desired objective. By using the app to tag and optimize more than 4,000 data points effortlessly, the team could perform hours of work in just a few clicks.

“What would have taken hours of work going through 4,000 different data tags that we use on our machine, we’re able to do in just a few clicks.”

Tyler Shirley, Asset Development, Electrical Engineer at Kimberly-Clark

With the help of Braincube’s wide array of advanced tools, Kimberly-Clark can close the production loop and operate more sustainably. Kimberly-Clark continues utilizing Braincube to visualize trends, analyze problems, and collaborate across departments.

Maximize your human potential. Achieve profitable performance. Drive your continuous improvement forward. See why industrials choose Braincube.

By leveraging IIoT technology, CPG manufacturers can significantly improve their production performance, boost profitability, stay ahead in a highly competitive market, and rapidly adapt to changing business needs.

By choosing the right condition-monitoring software, you can proactively monitor the performance of your machines and assets from anywhere, allowing you to access real-time condition data to optimize efficiency and maximize production value.

Discover how self-service analytics applications and IIoT platforms can help your company reduce unplanned downtime and increase productivity.