Revolutionize your paper manufacturing with AI-driven optimization. Enhance efficiency, cut costs, and achieve autonomous operations like industry leaders Arjowiggins and Oji Paper. Embrace the future of smarter production!

Learn more

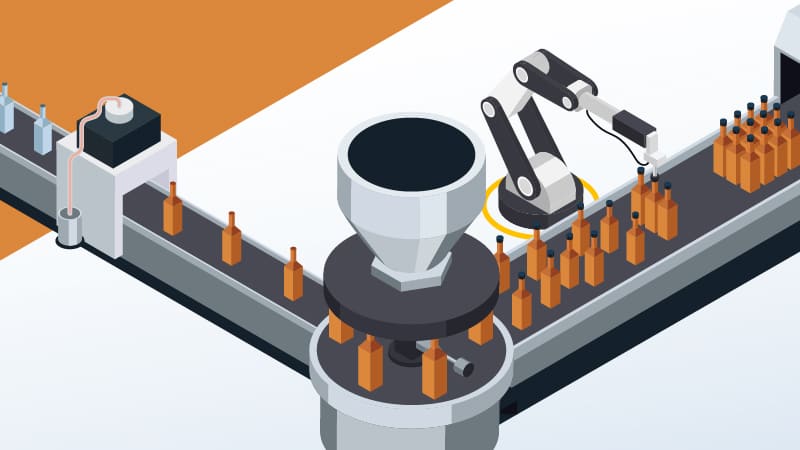

By 2025, the global alcoholic beverage market is expected to reach $2.3 trillion USD—with spirits accounting for about 25% of the overall market. Despite the growth, there are challenges challenging spirit manufacturers. Quality can be fickle. Raw material costs are cutting into your bottom line. And energy conservation is a goal among many.

Consistent taste and the utmost quality are essential to spirit manufacturers, master distillers, and their loyal customers. Data can help the talented people working within your facility make better decisions, know when something is off, and build upon their intrinsic knowledge.

Today’s Industrial Internet of Things (IIoT) tools and technologies put valuable data into the hands of your employees so they can work their magic.

For beverage manufacturers, quality can also be a fickle thing to maintain and perfect. Luckily, today’s IIoT tools can help. Learn more.

Since implementing Braincube, ofi improved its yield by 6.5% and achieved a 100% quality score on a key product line by implementing new AI-recommended rules

Digital Twins can be built for any part of your process or any physical entity. In this article, we unpack a few different types of Digital Twins found in manufacturing, including the pros and cons of each type.