Revolutionize your paper manufacturing with AI-driven optimization. Enhance efficiency, cut costs, and achieve autonomous operations like industry leaders Arjowiggins and Oji Paper. Embrace the future of smarter production!

Learn more

35% reduction in waste with AI

RESULTS

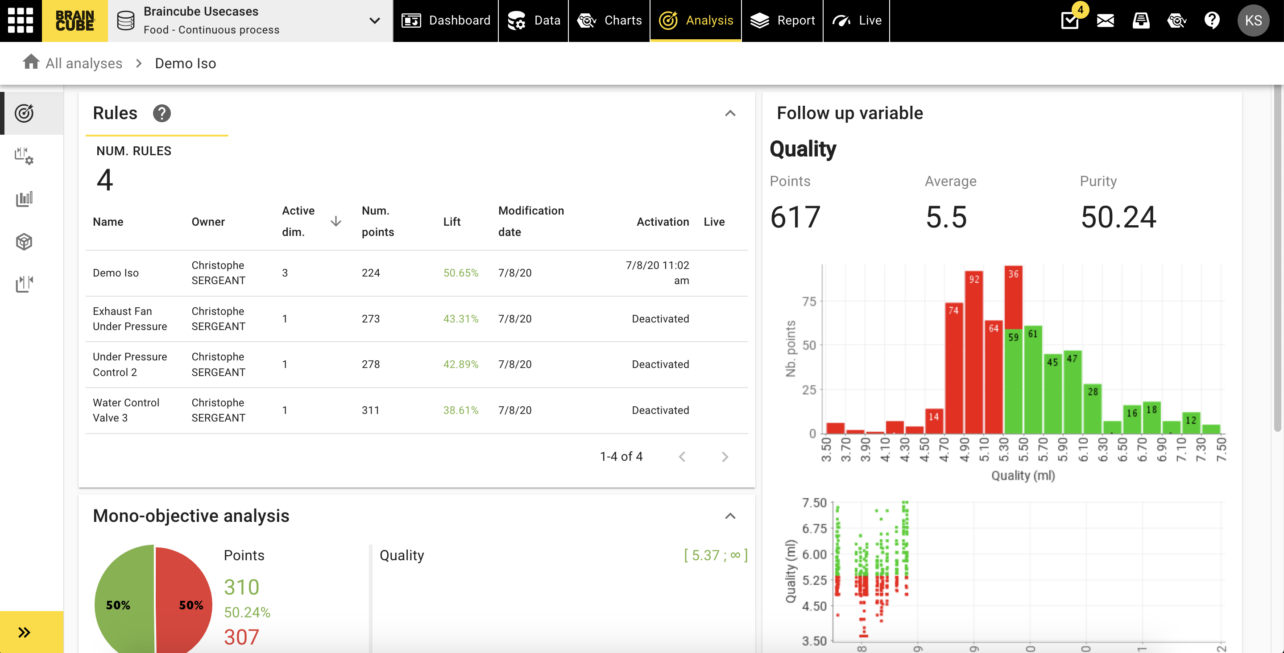

A global tire company developed a corporate strategy to scale cost-reduction efforts. They believed that AI could help them expedite their savings toward waste reduction.

The team had access to production data but struggled to consistently identify the most impactful process parameters that generated waste. They discovered that Braincube’s AI-based analytics tools would help them reduce variability, waste, and costs on a global scale.

Braincube’s CrossRank AI, known for its ability to crunch Big Data in seconds, helped teams isolate the input variables with the most significant impact on waste for a key process. AI also recommended optimal set points for operating at maximum efficiency.

Once the new standards went live, teams incorporated new data in their AI analyses and made additional optimizations as part of their continuous improvement strategy. These new standards significantly reduced variability within this single process step and resulted in a 35% reduction in waste. The company estimates this will save them over $1 million in one year.

Establishing—and updating—their global product tagging system enabled the company to streamline Braincube’s implementation at other sites. IT teams developed protocols to ease the transition and scale new technology. Democratizing their data has improved cross-departmental and plant-to-plant collaboration across 20+ worldwide facilities as part of their holistic digital transformation.

Maximize your human potential. Achieve profitable performance. Drive your continuous improvement forward. See why industrials choose Braincube.

Our on-demand video webinar explores how Edge AI streamlines operations in real-time, maximizing your productivity, and profit margins.

Advanced product traceability allows teams to reproduce Golden Batches, identify areas for improvement, and ensure the smooth running of operations. Here are six challenges you can overcome with traceability.

IIoT Platforms and self-service analytics applications make it easier to anticipate and reduce unplanned downtime. Learn how in this white paper.