Granting teams access to clean, contextualized data is an economical way for paper manufacturers make valuable process improvements. Plus, these solutions lay a vital foundation for advanced analytics and AI tools.

Learn more

Granting teams access to clean, contextualized data is an economical way for paper manufacturers make valuable process improvements. Plus, these solutions lay a vital foundation for advanced analytics and AI tools.

Learn more

Ready to revolutionize paper manufacturing? Unlock the potential of AI for your paper production! Get actionable insights in just 5 minutes to streamline operations, boost efficiency, and stay ahead of the competition. Take our quick AI-Readiness Assessment today!

Learn more

For the fourth time, Braincube has been named in the 2024 Gartner® Magic Quadrant for Global Industrial IoT Platforms. We believe our expertise in vision and execution—tailored to manufacturing—are driving forces for this recognition.

Read more

Discover how engineering teams can ensure manufacturing repeatability in the face of endless variability. Learn key strategies and tools for maintaining quality standards in changing conditions for streamlining production processes.

Learn more

Braincube’s Digital Twins and Digital Threads simulate production processes with precision, optimize production, personalize products, enhance quality, and satisfaction. Unlock the power of Industry 4.0 with Braincube’s state-of-the-art technology.

Learn more

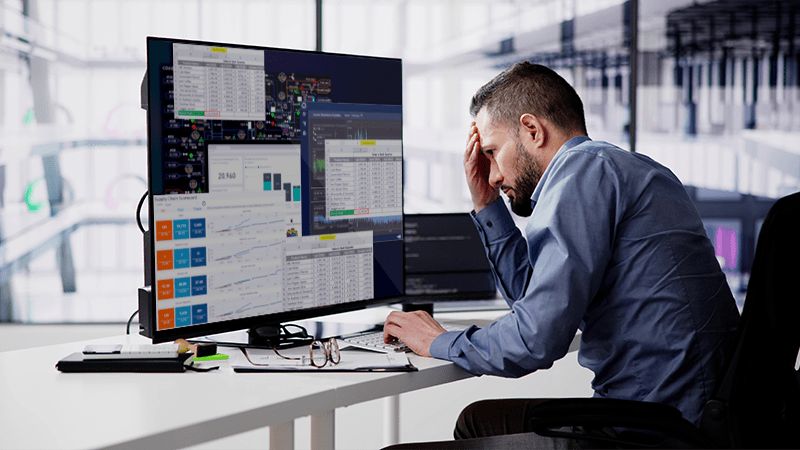

Optimize your manufacturing operations with proven strategies. Discover real success stories where operations directors have achieved more with fewer resources. Download the guide for practical insights on driving efficiency, motivating teams, and navigating change in the world of manufacturing.

Get the guide

In this white paper for engineering leaders, discover how multivariate analysis reveals deep process optimizations by unraveling the complex relationships that exist between manufacturing variables.

Get the white paper

In this webinar, you will learn about Digital Twins and its innovations through valuable customer stories about scaling 4.0, predictive analytics, and hyper-automation.

Learn more

Optimize your manufacturing operations with proven strategies. Discover real success stories where operations directors have achieved more with fewer resources. Download the guide for practical insights on driving efficiency, motivating teams, and navigating change in the world of manufacturing.

Get the guide

Manufacturing engineers have successfully used time series data to solve production challenges for years. But in today’s complex data landscape, is time series data sufficient on its own?

Learn more