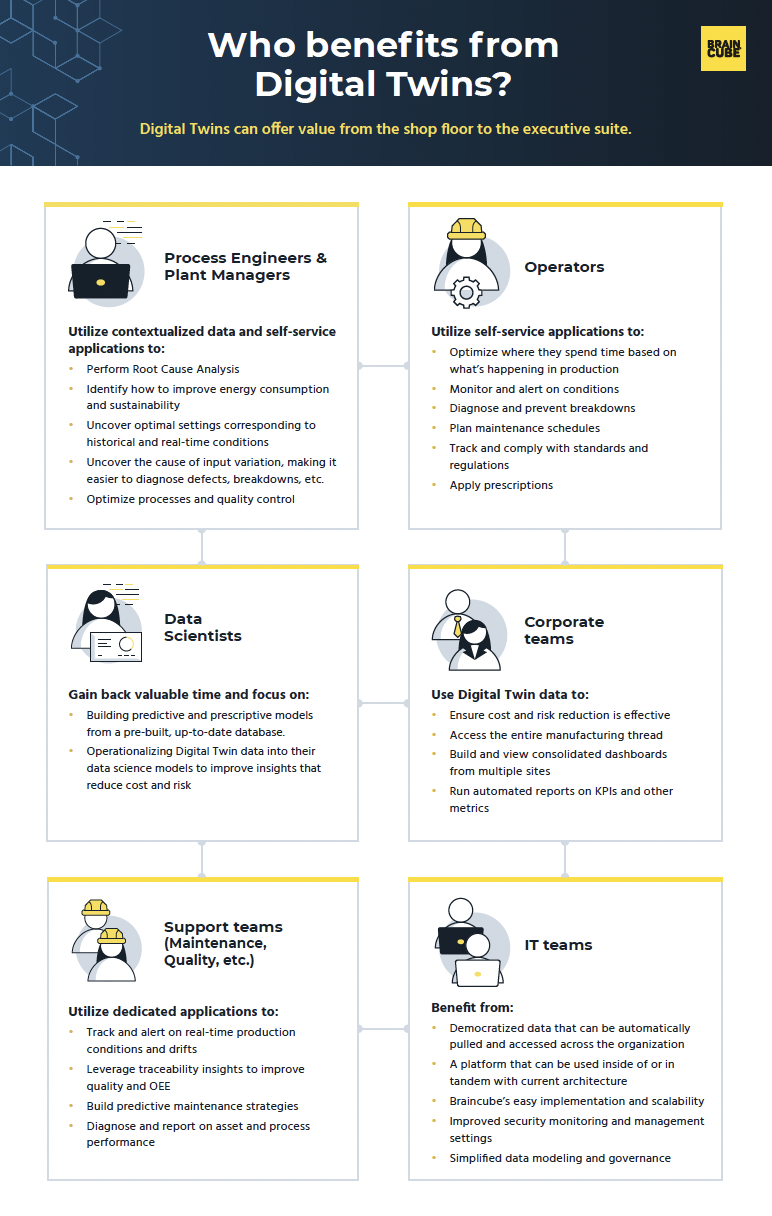

Digital Twins offer value to teams across your manufacturing company, ranging from the shop floor all the way to the C-Suite.

Braincube Digital Twins help manufacturers save time, improve efficiency, and fast-track continuous improvement efforts. They serve as the gateway to self-service analytics, data visualization, custom data science models, and other application use cases.

Digital Twins provide teams with an accurate, real-time, harmonized dataset to accelerate your business optimization. This data set can then be used across your data architecture.

Democratizing access to usable data makes your teams more efficient, focused, and collaborative, giving your company a competitive edge. Automating the tedious work of pulling, cleaning, and contextualizing data from different systems and formats ensures that ready-to-use dynamic data is centered around business optimization.