Revolutionize your paper manufacturing with AI-driven optimization. Enhance efficiency, cut costs, and achieve autonomous operations like industry leaders Arjowiggins and Oji Paper. Embrace the future of smarter production!

Learn more

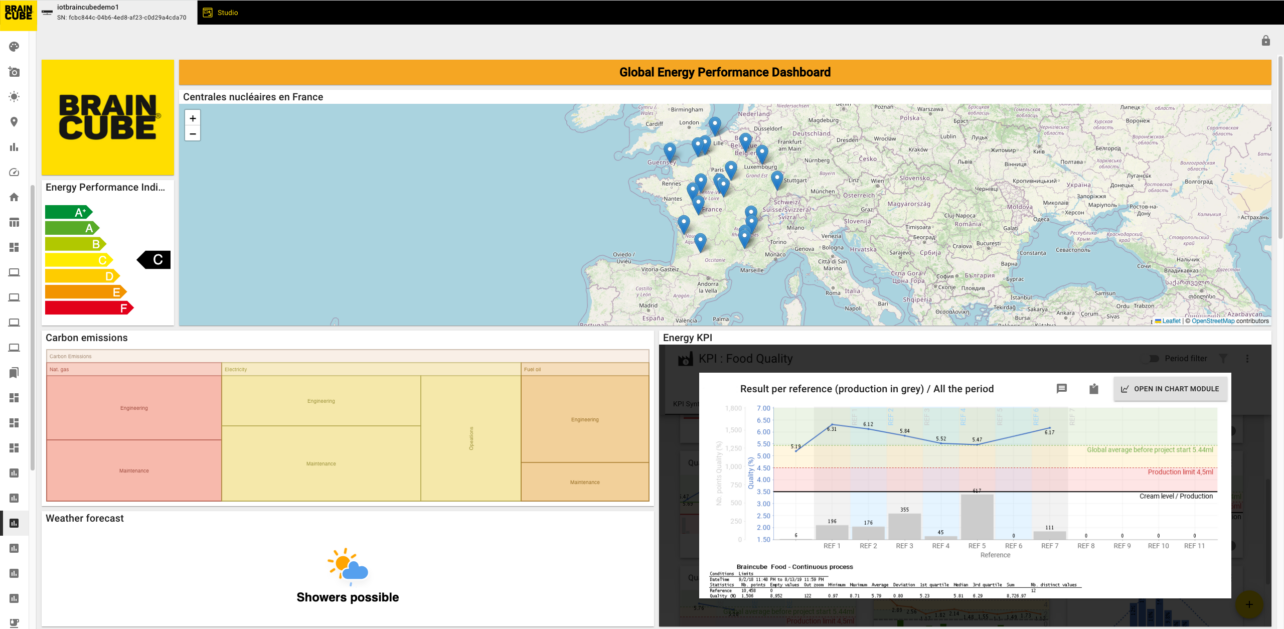

Implement changes within a single platform.

RESULTS

Energy management is an increasingly urgent priority for manufacturers. This is particularly true for manufacturers in the metallurgy industry, where 50% of total production costs come from energy usage.

Aubert & Duval, a leading European metallurgical manufacturer, wanted a digital solution to support its data, cost improvement, and sustainability strategies at their Ancizes site. The goal was to lower their annual energy consumption expenses by 15%, comply with ISO 50001 standards, and optimize their EnPIs (Energy Performance Indicators) for better energy efficiency.

To effectively accomplish their sustainability goals and adhere to regulations, Aubert & Duval Ancizes needed various tools related to energy usage analysis, tracking, and reporting. Their teams wanted to verify energy-reducing production hypotheses using timely data, then quickly push changes live for rapid results.

After evaluating multiple solutions, Aubert & Duval Ancizes implemented Braincube’s digital tools. Braincube’s dynamic toolset means teams can view, analyze, track, and implement changes within a single platform.

For example, Braincube’s Advanced Analysis App pinpoints the most impacting variables on the team’s energy consumption and efficiency. These valuable insights can be implemented directly on the shop floor for immediate energy savings.

Data visualization tools, like Braincube’s Studio App, enabled the teams at Aubert & Duval Ancizes to build custom energy-tracking dashboards for every batch, department, and piece of equipment. These dashboards automatically track and report on production performance KPIs, simplifying the building of monthly and weekly energy reports.

“Democratizing energy tracking and reporting with automated dashboards was a stepping stone to go above and beyond our sustainability goals. It helped us drive our efforts on the most significant energy uses, focusing on the right process, equipment, or production planning.”

Benoit Cugnet, Energy Engineer at Aubert & Duval Ancizes.

Braincube’s Digital Twins are at the heart of their energy management strategy, enabling teams to track batch efficiency, monitor processes, and optimize equipment utilization more accurately. Now, teams are building predictive models utilizing Braincube’s analytical tools for predictive maintenance, planning production more efficiently, and foreseeing their energy needs.

The organization-wide push to digitize their operations, prioritize sustainability efforts, and automate monitoring and reporting tasks proved fruitful. Combined, these strategies helped the Aubert and Duval Ancizes site successfully reduce their electricity consumption by 3% and gas usage by 19%.

Maximize your human potential. Achieve profitable performance. Drive your continuous improvement forward. See why industrials choose Braincube.

Meeting customer and quality demands is crucial for mines and metals manufacturers. Learn how to ensure that the right specifications are met throughout the production process, providing value to customers.

Braincube’s IIoT tools help mines and metals companies reduce operational costs by consolidating and contextualizing data to minimize hazards and failures and improve predictive maintenance and reliability.

The challenges facing steelmakers today are complex and varied. Steelmakers can use Industrial IoT (IIoT) tools to adapt to changing global, environmental, and national conditions.