Roofing materials

Building Materials Company

A Braincube building materials customer needed a solution that enabled their engineers to instantly analyze and visualize data generated by the production line to identify and resolve product variability. Learn how Braincube’s Digital Twin helped them uncover an unexpected root cause of their challenge.

Topics: Recipe optimization, Standardization, Quality, Cost Savings, Digital Twin, Dashboards, Roof shingles, Building materials

OEE

CPG Company

Improved access to real-time data enabled a global CPG company to improve efficiency, uptime, and optimize its resources. This CPG company hoped to improve their OEE by more than 20%. They were able to exceed this goal using Braincube’s applications and Digital Twin data.

Topics: OEE, Cost savings, Edge analytics, Reduced downtime, CPG

Sustainability

CPG Company

A large CPG company used Braincube’s technologies to uncover the exact settings needed to operate at prime efficiency. Braincube’s advanced analytics were able to optimize their end-to-end manufacturing process and they have seen gains in energy savings, reduced waste, cost savings, process stabilization, and more.

Topics: Sustainability, Standardization, Cost Savings, CrossRank AI, BI Apps, CPG

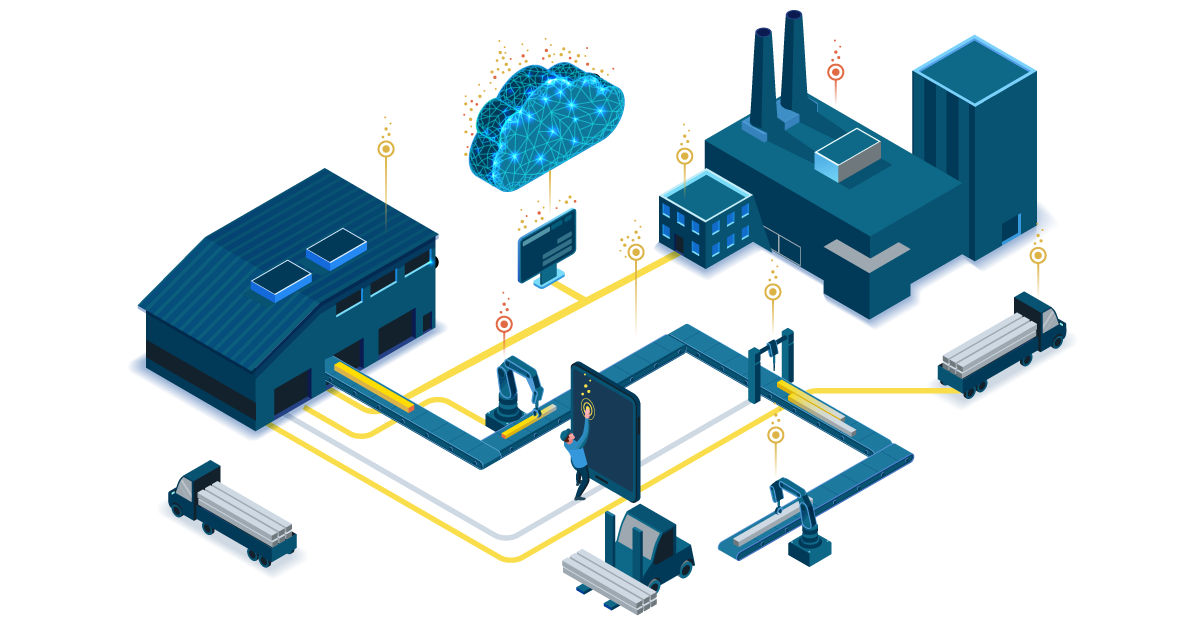

Steel

Steel Company

Steel Company X*, one of the largest steel producers in Brazil with over 20,000 employees, chose Braincube to help their digital transformation process. Download the case study to learn how they achieved 20x ROI and saved over $1.4 million using Industry 4.0 tools.

Topics: Quality, Traceability, Cost Savings, Digital Twin, Steel

CPG

Decathlon

With objectives ranging from improving performance, profitability, competitiveness, agility, and even safety, Decathlon needed a customized, holistic solution to gain access to their disparate real-time and Cloud data in one centralized platform. Learn how Decathlon leveraged the Edge Factory Box by Braincube and Siemens to improve product quality, safety, and daily performance.

Topics: Agility, Safety, Cost savings, Edge Analytics, CPG

Food ingredients

Avril

When they reached an improvement plateau, they turned to new tools to help uncover additional improvements to their complex processes. Avril’s implementation of Braincube led to better sales and storage forecasts, the implementation of dashboards to track relevant KPIs, and the autonomy to make improvements based on changing business and economic needs.

Topics: Holistic transformation, Digital Twins, Cost savings, Food

Food & Beverage

ofi

Ofi wanted to stabilize and fine-tune one of their product lines in an effort to improve overall yield. The teams were manually collecting data and performing calculations, but they couldn’t get the level of detail they needed to significantly improve their production processes.

Topics: Quality stabilization, Improve yield, Digital Twin, BI Apps, Platform, Food

Pulp & Paper

Sappi

As part of their sustainability journey, Sappi needed a Cloud and Edge platform solution that enabled them to set governance standards at the enterprise level. They also wanted to equip their domain experts with data science tools.

Topics: Scaling IIoT, Connectivity, Change management, Hybrid, Paper, Pulp

Energy & Chemical

Chemical Company

Chemical Company X used Braincube to improve their distillation process by 36% and has saved over $1 million in two years. They also established standardized production procedures at multiple facilities to reduce cost and waste. Learn more in their case study.

Topics: Visualization, Improve yield, Cost savings, Oil & Gas, Chemical, Energy

Tire Company

A global tire company implemented Braincube to minimize waste, save money, and improve quality. They achieved their objective in just a few months and minimized waste by 35% within their target process, resulting in $1 million in savings per year. This was only the start of their IIoT success.

Topics: Quality, Cost Savings, Minimize waste, Elastomer, Tires